Edward W. Bullard

Edward W. Bullard invented the hard hat, the first commercially available industrial head protection device. Bullard’s lightweight, non-conducting hard hat design was sturdy enough to withstand many falling objects. This invention has since become a mandatory piece of equipment for protecting millions of workers around the world.

Bullard was born in 1893 in Las Vegas, New Mexico. A graduate of Lowell High School in San Francisco, and the University of California, Berkeley, he served in the cavalry of the U.S. Army and was stationed in France during World War I. Bullard served for nine months and achieved the rank of lieutenant.

Upon returning home, Bullard joined the E.D. Bullard Co. in San Francisco. The company had been founded in 1898 by his father, Edward Dickinson Bullard, to sell carbide lamps and mining equipment to gold and copper miners. Through this work, Bullard soon noticed a common hardship for miners — they had no head protection from life-threatening falling debris. Recalling the steel “doughboy” helmets he and fellow soldiers had worn in France, he was inspired to develop a safety helmet based on the same design for miners and others engaged in dangerous work.

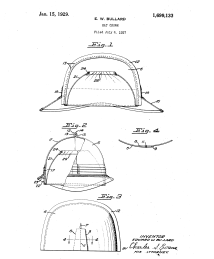

In 1918, Bullard began turning his idea into a reality. To create this new helmet, he used alternating layers of sturdy canvas and glue. Steaming the stiff canvas to make it temporarily pliable, he glued together overlapping layers to form the shell. Then he covered the shell inside and out with water-resistant shellac for added strength and durability, and he added leather front and rear brims.

Bullard initially called this helmet the Hard Boiled Hat®, referring to the steam used in its manufacturing process. It was patented and entered production in 1919.

The Hard Boiled Hat met miners’ needs and quickly spread to other industries. Its use in work zones soared during the major construction projects of the 1930s, including both the Hoover Dam and Golden Gate Bridge projects. These defining industrial projects of the Great Depression era required a significant amount of risk.

Golden Gate Bridge engineer Joseph B. Strauss was committed to implementing new safety standards, and he contacted Bullard to request that the company adapt its hats to protect bridge workers. In order to mitigate the danger of falling rivets from the bridge project, Bullard transformed the original mining helmet into a durable industrial hard hat. This led to the Golden Gate Bridge project becoming known as America’s first designated “Hard Hat Area” in 1933.

Also in 1933, the Bullard company offered its first aluminum hard hat, as well as its first fire helmet, which was based on the Hard Boiled Hat design. Bullard went on to patent several more improvements to his original design, including an adjustable suspension system that distributes the force of a blow. In the 1940s, the Bullard company introduced the well-known three-rib hard hat design and the first fiberglass fire helmet. In the 1950s, the company created the first thermoplastic hard hat and opened a molding department to manufacture plastic helmets.

The significance of the hard hat has been reinforced through the decades. Established in 1971 , the Occupational Safety and Health Administration (OSHA) required workers to wear hard hats on job sites, and since then, the number of worker deaths has substantially decreased, demonstrating the importance of head protection in the workplace. Approximately 6 million hard hats are now sold annually.

With the introduction of the hard hat more than 100 years ago, the Bullard company expanded and began manufacturing industrial safety equipment. Owned by the Bullard family and led by E.W. Bullard’s great-granddaughter Wells Bullard, today the company is a leading manufacturer of personal protective equipment and systems that are marketed worldwide.