Mick Mountz

"One of the fun things about being an inventor or an innovator or an entrepreneur is thinking outside the box."

Mick Mountz, Peter Wurman and Raffaello D’Andrea invented the Kiva system, a mobile robotic material handling system that has revolutionized order fulfillment.

In an interview with the National Inventors Hall of Fame®, Mountz said he inherited the curiosity that led him to become an inventor and entrepreneur from his mother, a botanist and amateur biologist who saw even everyday chores as chances to experiment. Mountz recalled how his mother sparked his curiosity while doing laundry. “She’d closed all the curtains and started taking the laundry out of the dryer,” he said. “Static electricity sparks were lighting up the whole room. She was showing me static electricity in the dryer.”

Mountz also developed a collaborative spirit in his early years. Born in a U.S. Army Hospital in Frankfurt, Germany, where his parents were stationed, he lived in 13 different places including Korea, Italy, Wisconsin, Illinois and Georgia before attending college. He learned that participating in sports helped his family to quickly feel at home in new communities, and lessons in teamwork eventually made an impact in his career. Mountz explained, “Having parents who challenge you to play sports, pick leadership roles, be curious — I think all of that contributes to how you move through your education process and then some of your career decisions as well.”

He earned his bachelor’s degree in mechanical engineering from the Massachusetts Institute of Technology (MIT) in 1987 and his MBA from Harvard University in 1996. He began his career with Motorola and later joined Apple Inc., but it was his experience at Webvan, an online grocery home delivery company, that allowed Mountz to understand challenges in material handling and distribution operations.

While e-commerce was growing rapidly during the 2000s, material handling within distribution centers still relied on decades-old techniques that were inefficient for order fulfillment in the era of online shopping. In 2002, Mountz began developing an idea that would radically change this.

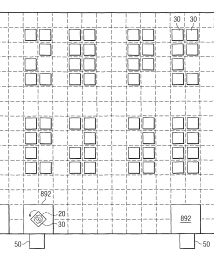

To help create an efficient method for order fulfillment, Mountz asked Wurman, his former MIT roommate and a North Carolina State University professor, for software advice. Together, they decided on a centralized software architecture to wirelessly command a fleet of robots in real time. D’Andrea, a robotics and controls expert and professor from Cornell University, soon joined their company, then known as Distrobot, to develop the movement layer. Using thousands of mobile robots and sophisticated control software, the team created a groundbreaking system that brings inventory shelves to workers, dramatically improving all areas of fulfillment center operations, from safety and productivity to cycle time and throughput.

In 2005, Distrobot became Kiva Systems Inc. and produced the first commercially available, large-scale, autonomous mobile robot system. By 2012, Kiva served dozens of customers including Staples, Walgreens, Zappos, the Gap and Saks Fifth Avenue. That same year, Amazon purchased Kiva Systems. By 2013, Amazon reduced its “click-to-ship” time from 60-75 minutes to just 15 minutes per order. “And here in 2024, Amazon is approaching almost 1 million Kiva bots in operation across their fulfillment centers worldwide,” said Mountz.

A member of the MIT Corporation and the School of Engineering Dean’s Advisory Council, Mountz holds more than 60 U.S. patents. Through his involvement with Camp Invention®, he has encouraged the next generation of innovators, explaining, “That’s the kind of thing I’m trying to pass along — a curiosity and a sense for discovering solutions to tough problems.”