Ming-Jun Li

"It’s always important for a team to have people with different technical backgrounds, different ways of thinking. This is how you can get different perspectives, different opinions."

Ming-Jun Li, Dana Bookbinder and Pushkar Tandon invented bend-insensitive optical fiber. This technology can bend without causing significant signal loss, enabling the installation of optical fiber in previously impossible locations and advancing the process of data transmission.

Li was born in Beijing, China, in 1959. Following a delayed start to his education due to China’s Cultural Revolution, he entered elementary school at age 8 and recalls that exposure to typical academic subjects beyond language and mathematics was limited at that time. However, once he entered high school, he began to develop an interest in science.

At Beijing Institute of Technology, Li earned his bachelor’s degree in applied physics in 1983. He then completed his graduate studies in France, earning his master’s degree in optics and signal processing from the University of Franche-Comté in 1985, followed by his doctorate in physics from the University of Nice in 1988. At the Integrated Optics Laboratory of Ecole Polytechnique de Montreal in Canada, Li completed his postdoctoral fellowship in 1990.

In 1991, Li began working as a research scientist at Nortel Networks Corp., and in 1994 he joined Corning Inc., where he is currently a Corporate Fellow. He has described working for Corning as his “dream job” since he learned in college that Corning invented the first low loss fiber, and in a conversation with the National Inventors Hall of Fame®, Li praised Corning’s culture: “I think the innovation culture is really important. In Corning, everybody is encouraged to discover new things, to come up with new designs, new innovations.”

Here, he began working with Bookbinder and Tandon, and the team began conducting experiments with optical fiber. “Optical fiber is so thin,” Li said. “The diameter is like a human hair. And the light can go through that thin glass for hundreds to thousands of kilometers — to me that was magic.”

Before optical fiber, copper wire was used to transmit phone calls and data over long distances. Copper uses electric current, while optical fiber sends pulses of light. Fiber is less vulnerable to electromagnetic interference and can transmit far more data. However, conventional optical fiber required long, straight cables to transmit data without significant signal loss, and it could not transmit light around tight bends.

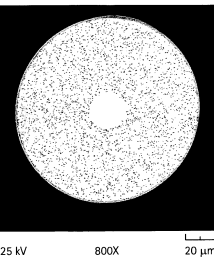

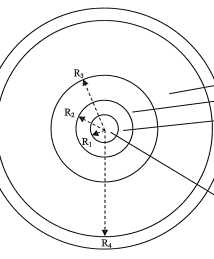

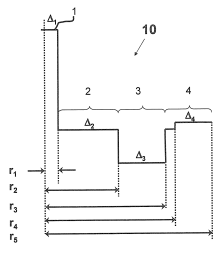

Li, Bookbinder and Tandon discovered that certain types of optical fiber could transmit light around tight bends when they explored wrapping the material around a cylindrical rod and saw that the light continued traveling through the fiber and out the other end. The team created a fiber that caused light beams to be reflected smoothly back into the core rather than diffracted in the cladding at a sharp bend.

Introduced by Corning as ClearCurve® in 2007, this new fiber had a core surrounded with a low refractive index “optical trench.” The fiber structure was optimized for both single-mode fiber and high-bandwidth multimode fibers that were fully standards-compliant for fiber-to-the-home and data center applications.

Bend-insensitive optical fiber “can make optical communication systems better, and also make people’s lives better,” explained Li. “When any fiber is used for that, I always feel very good about it. I’m very proud of that.”

Li shares several awards for ClearCurve optical fiber with Bookbinder and Tandon. He is the recipient of the 2023 John Tyndall Award, fiber-optic technology’s highest honor. He holds more than 290 U.S. patents.